Abstract

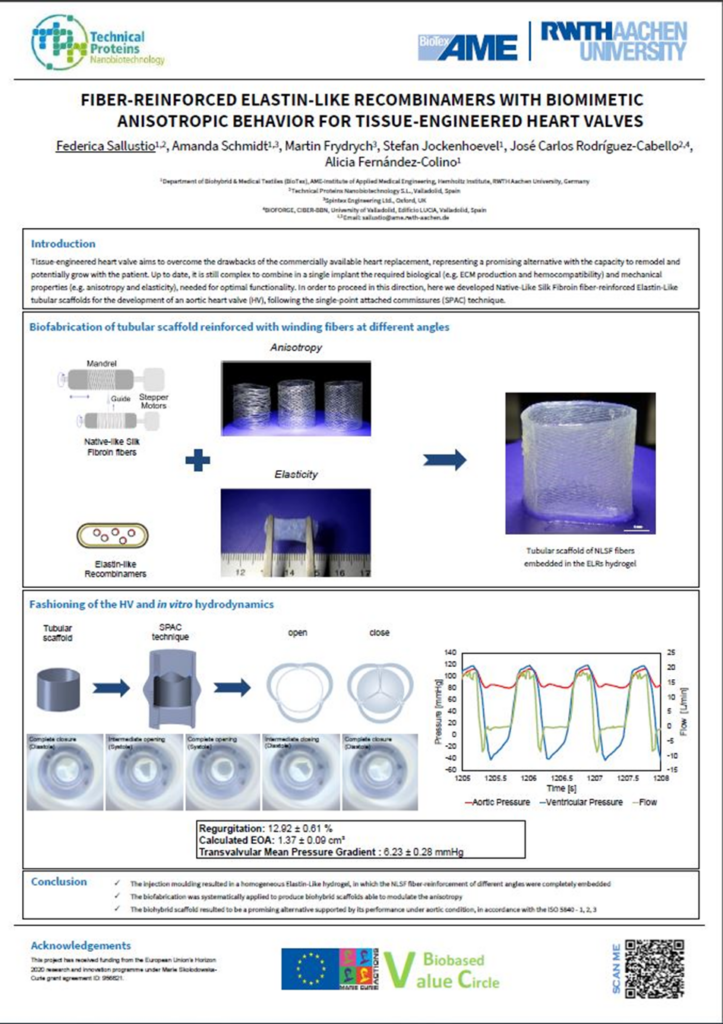

Over the last 30 years, tissue-engineered heart valves target to a replacement that is able to remodel and grow with the patient, reducing the risk of multiple surgeries caused by the current commercially available heart valve substitutes. However, this field of research is still ongoing and few attempts have been done towards a complete growing valve, although a clinically viable tissue-engineered heart valve has yet to be developed (Nachlas et al., 2017; Stassen et al., 2017). Therefore, the biological materials to mimic the native tissue is compelling. Herein, we propose a novel biohybrid aortic valve composed of Elastin-Like Recombinamers to resemble the extracellular matrix that compose the native tissue and Native-Like Silk Fibroin (NLFS) fibers to mechanically support the valve performance, in an analogous manner to the collagen fibers. These two biological materials were successfully combined in a tubular shape that exhibited a modulation of the anisotropic behaviour according to the change of the NLFS fibers angle (5°, 15°, 25° and 45°). Subsequently, the most suitable, that matches biological and mechanical properties, was selected to be fashioned in a valve and subjected to aortic conditions to further evaluate its performance. The biohybrid aortic valve met the regulations imposed by the ISO guidelines for heart valve replacement with transcatheter techniques, proving its capability to be a candidate for aortic valve replacement in order to overcome the limitations for the commercially ones and guarantee a better quality of life to the patients.

Publications for Communication and Dissemination

2 papers in indexed journals before the PhD thesis lecture are planned.

The first paper, concerning a more in-depth investigation of the anisotropic scaffolds presented here, is under internal review and is scheduled to be submitted in a few months.

Abstract submission entitled “Fiber-reinforced Elastin-Like Recombinamers with biomimetic anisotropic behaviour for tissue engineered heart valve application” to the 33rd Annual Conference of the European Society for Biomaterials which took place on September 4th – September 8th 2023 in Davos, Switzerland (https://esb2023.org/ ).

The targeted actors could belong to both academia and commercial industries. The aim of the research is to provide an adequate alternative to overcome the drawbacks related to the gold standards in AV replacement, therefore people involved in the fields of tissue engineering, regenerative medicine, biobased-materials and biomedical application could be interested in the research. Collaborations to make changes or improvements to the research could be started, taking advantage of the knowledge of all parties involved.

Protection of the acquired intellectual property (patents applications) etc.

Now, according to the project’s update, no intellectual properties have been granted.

Impact on science and/or technology

We have developed knowledge about the application of ELRs for the consecution of anisotropic tissue-mimetic scaffolds. The process starts with the genetic engineering of the elastin-like materials and ends with the fermentation of the bacteria in a bioreactor. These two methods have been exploited for the final purpose of a protein-based materials bioinspired by natural elastin. Its introduction in the topic of AV is a step towards innovation, regarding the advantages of this material, related to bio- and immuno-compatibility along with providing fatigue-resistance, and the actual limitations of the available devices on the market. Currently, there is no elastin-based valve replacement clinically available. This project therefore aims to push the boundaries of (biobased) materials science, to develop innovative implants not yet available in the market.

Impact on science and/or technology

We have developed knowledge about the application of ELRs for the consecution of anisotropic tissue-mimetic scaffolds. The process starts with the genetic engineering of the elastin-like materials and ends with the fermentation of the bacteria in a bioreactor. These two methods have been exploited for the final purpose of a protein-based materials bioinspired by natural elastin. Its introduction in the topic of AV is a step towards innovation, regarding the advantages of this material, related to bio- and immuno-compatibility along with providing fatigue-resistance, and the actual limitations of the available devices on the market. Currently, there is no elastin-based valve replacement clinically available. This project therefore aims to push the boundaries of (biobased) materials science, to develop innovative implants not yet available in the market.

Impact on innovation (companies)

The innovation relies in the use of “green” biobased materials, like the ELRs and NLSF fibers, which have demonstrated to be combined in order to develop a scaffold that is biocompatible and with suitable mechanical properties for an AV substitute. These two materials have never been utilized from a company to design a product; however, it can be interesting for biomedical companies to get involved in the use of this approach thanks to the benefits related to origin of the materials and their straightforward processability in hydrogels and fibers, respectively, making this technique unscalable and suitable for biomedical companies well established in the market. Moreover, the generated knowledge regarding the production, purification and modification of ELRs fits within the overall aim of the consortium: to establish a paradigm shift in the innovation process for biobased materials to accelerate the transition from a fossil-based to a biobased and circular economy.

Impact on society

The expected impact of the results on society targets directly the patients suffering from heart valve diseases. Currently the treatment options are suboptimal, leading to a decreased quality of life; however, the developed implant as AV replacements is a suitable candidate to overcome the drawbacks present in TEHV prototype and commercially available options.

Visual Summary – Poster