Abstract

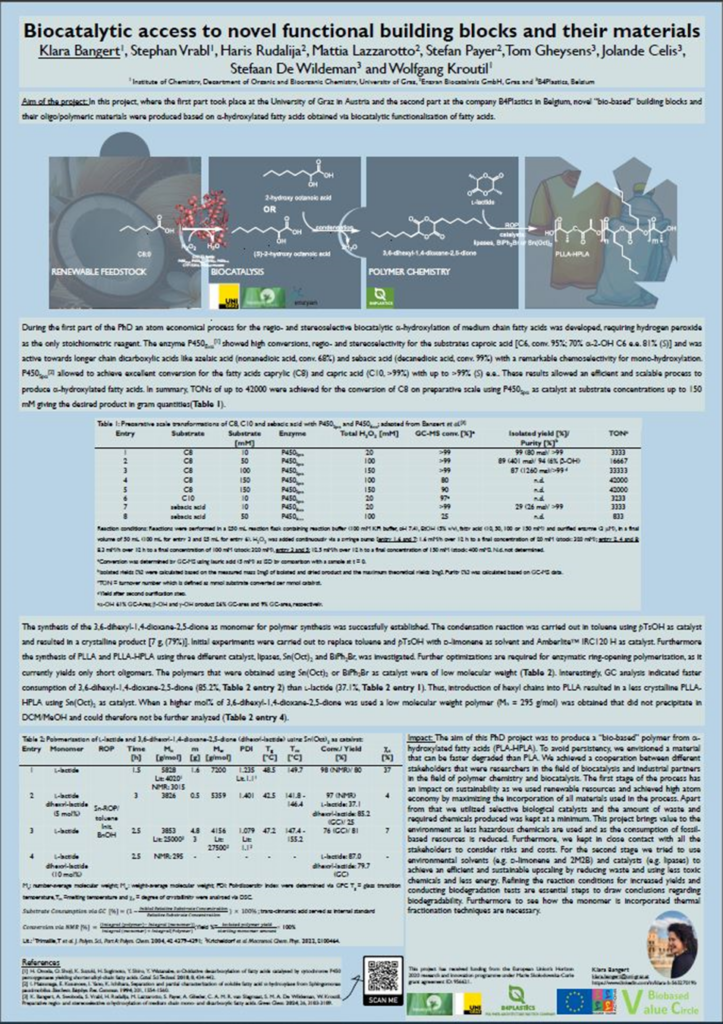

The aim of this PhD was to investigate options to make building blocks for “bio-based” polymers from fatty acids and to invstigate polymer formation. The focus during the first part of the PhD at the University Graz was on the CYP152 family which are P450 peroxygenases that utilise fatty acids as natural substrates and can be used for the biocatalytic -functionalization of medium chain fatty acids. Enzyme candidates of the CYP152 family were selected, expressed, purified and the conversion of medium-chain fatty acids was investigated. The primary objective was than an upscale of the production of α-hydroxylated fatty acids.

The secondment took place at the company B4Plastics where the main aim was to find and select possible strategies to design and produce bio-based polymers from α-hydroxylated fatty acids in an industrially oriented framework. Initially, a protocol was developed to synthesize alkyl lactides from α-hydroxylated fatty acids. The emphasis was placed on the utilization of a α-hydroxylated fatty acid successfully synthesized in the initial phase of the PhD. For the second step the idea was to synthesise a copolymer using L-lactide. The reaction conditions for ring-opening polymerisation (ROP) were optimized by applying different temperatures, conducting the reaction in an organic solvent or solvent-free and by using different catalyst as Sn(Oct)2, BiPh2Br and lipases and initiators. Moreover, the effect of the aliphatic side branch was analysed by determining the melting point, molecular weights, glass transition temperature and crystallinity of PLLA and the newly synthesized “bio-based” polymer. The latter is expected to show higher biodegradability than PLLA.

Publications for Communication and Dissemination

- K. Bangert, A. Swoboda, S. Vrabl, H. Rudalija, M. Lazzarotto, S. Payer, A. Glieder, C. A. M. R. van Slagmaat, S. M. A. De Wildeman, W. Kroutil, Preparative regio- and stereoselective α-hydroxylation of medium chain mono- and dicarboxylic fatty acids. Green Chem. 2024, 26, 3183-3189.

- Swoboda, L. J. Pfeifenberger, Z. Duhović, M. Bürgler, I. Oroz-Guinea, K. Bangert, F. Weißensteiner, L. Parigger, K. Ebner, A. Glieder, W. Kroutil, Enantioselective High-Throughput Assay Showcased for the Identification of (R)- as well as (S)-Selective Unspecific Peroxygenases for C−H Oxidation. Angew. Chem. Int. Ed. 2023, 62, e202312721.

Target Groups:

Academic partners: Our research focuses on the use of fatty acids as renewable resource and combine it with biocatalysis to transform the fatty acids into building blocks for new plastics. We like to address the Biocatalysis Community with our research and demonstrate a broader application range of the used enzyme class.

Attended conferences:

- K. Bangert, C. van Slagmaat, K. van Tilburg, J. Celis, S. De Wildeman, W. Kroutil (2022, June).Transformation of fatty acids into building blocks for new plastics [Poster]. Biocatalysis for the Biological Transformation of Polymer Science, Köln, Germany.

- K. Bangert, C. van Slagmaat, K. van Tilburg, J. Celis, S. De Wildeman, W. Kroutil (2022, August). Transformation of cheap renewables into polymeric bioproducts [Poster]. 10th International Congress on Biocatalysis (biocat2022), Hamburg, Germany.

- K. Bangert, C. van Slagmaat, T. Gheysens, K. van Tilburg, J. Celis, S. De Wildeman, W. Kroutil (2023, June). P450 peroxygenases – regio- and stereoselective hydroxylation of fatty acids [Poster]. International Symposium on Biocatalysis and Biotransformations, (BIOTRANS 2023),La Rochelle, France.

- K. Bangert, T. Gheysens, J. Celis, S. De Wildeman, W. Kroutil (2023, September). Preparative scale synthesis of α-hydroxylated fatty acids with P450 peroxygenases [Presentation].International Symposium on Synthesis and Catalysis 2023 (ISySyCat2023), Évora, Portugal.

Industry partners:

The aim is to produce new building blocks, -hydroxylated fatty acids, for the production of new polymers. These build blocks but also new polymers are in first line of interest for B4Plastics. We cooperated with Enzyan, a start-up at University Graz. They did an upscale of the first step of the PhD project which is the production of (S)- -hydroxy octanoic acid.

General public : We launched a press relase of our publication in Green Chemistry.

Universität Graz. (2024, January 24). Plastic from coconut oil? Graz researcher develops new building blocks for bioplastics [Press release]. https://www.uni-graz.at/en/news/kunststoff-aus-kokosoel-grazer-forscherin-entwickelt-neue-bausteine-fuer-bioplastik/

This caught interest of a broader audience and appeared in following TV program and newsletters.

ORFTVTHEK- Mayrs Magazin – Wissen für alle. (February 2, 2024). Kunststoff aus Kokosöl [TV Program]. https://tvthek.orf.at/profile/Mayrs-Magazin-Wissen- fuer-alle-OeGS/13892845/Mayrs-Magazin-Wissen-fuer-alle-vom-02-02-2024-OeGS/14212237/Kunststoff-aus-Kokosoel/15566960

Science ORF. (January 24, 2024). Kokosöl als Basis für stabileres Bioplastik [press release]. https://science.orf.at/stories/3223284/

Die Presse. (January 27, 2024). Maiskeimöl und Kokosöl als Basis für Kunststoff [Pressemitteilung]. https://www.diepresse.com/18033023/maiskeimoel-und-kokosoel-als-basis-fuer-kunststoff

| Action | Target actors/audience | Means | Timing |

| Groupmeeting in Graz | Research group Graz- Biocatalysis | Presenting | February, 2022 |

| YouTube Channel ElkCrew presentation Alcohol Oxidases online | youtube | Presenting | March, 2022 |

| Training events Biobased Value Circle #3 in Netherlands | Other ESRs and supervisors within the consortium | Presenting | May, 2022 |

| DocDays in Graz | Doctoral School Chemistry University Graz | Presenting | April, 2022 |

| Long night of research, Österreich in Graz | General public | Presenting | May, 2022 |

| Conference- Biocatalysis for the Biological Transformation of Polymer Science in Köln/Germany | Conference attenders | Presenting Poster | June, 2022 |

| 10th International Congress on Biocatalysis in Hamburg/Germany | Conference attenders | Presenting Poster | August, 2022 |

| Groupmeeting in Graz | Research group Graz- Biocatalysis | Presenting | September, 2022 |

| Training events Biobased Value Circle #4 in Cologne | Other ESRs and supervisors within the consortium | Presenting | November, 2022 |

| Group meeting in Graz | Research group Graz- Biocatalysis | Presenting | Februar, 2023 |

| DocDays in Graz | Doctoral School Chemistry University Graz | Presenting | April, 2023 |

| Training events Biobased Value Circle #5 in Graz | Other ESRs and supervisors within the consortium | Presenting | May, 2023 |

| Conference- Biotrans2023 in La Rochelle/ France | Conference attenders | Presenting | June, 2023 |

| Conference- International Symposium2023 in Evova/Portugal | Conference attenders | Presenting | September, 2023 |

| Publication in Green Chemistry | broader audience | Journal Green Chemistry, press releases, TV program | January, 2024 |

| LinkedIn Biobased Value Circle | Academic/Industry and general public; wide range of professionals | Promotion Responsible ESR for the pro-motion of all the work done in the the consortium and comm-unication sessions in social networks, especially LinkedIn. | xx |

Protection of the acquired intellectual property (patents applications) etc.

Not applicable.

Impact on science and/or technology

The research findings contribute to advancing scientific knowledge in the fields of biocatalysis, protein engineering, polymer chemistry and green chemistry.

During the first part of the PhD an atom economical process for the stereoselective biocatalytic -hydroxylation of medium-chain fatty acids was developed, requiring hydrogen peroxide as the only stoichiometric reagent. The enzymes showed high conversions, regio- and stereoselectivity for the substrates. These results allowed an efficient and scalable process to produce -hydroxylated fatty acids where the amount of required chemicals and waste produced were kept at a minimum. For the first time TONs of up to 42000 were achieved for the conversion of C8:0 on preparative scale using P450Spα as catalyst at substrate concentrations up to 150 mM giving the desired product in gram quantities. Our research can aid in technological advancements. The production of α-hydroxylated fatty acids is straightforward and does not require a complex set-up. It necessitates only the appropriate biocatalyst, fatty acids as the substrate, H₂O₂ as the oxidant and electron source, a buffer, and the correct co-solvent. In contrast to methods for in-situ generation of H2O2 and also in contrast to batchwise addition of H2O2, here the H2O2 was supplied by continuous feeding of an H2O2-solution to supplement the reaction overall with (at least) stoichiometric amounts of oxidant. Using this approach, we expected to avoid elevated concentration of H2O2. Furthermore, the local H2O2 concentration at the inlet was expected to be kept to a minimum by vigorous shaking or stirring.

At B4Plastics a bridge between biocatalysis and polymer chemistry was established to produce and degrade new polymers. This should strengthen the greener way of thinking in the plastic industry. Although enzymatic ring-opening polymerisation did not result in the expected polymers, initial experiments were conducted to produce polyesters under milder conditions.

Impact on innovation (companies)

The research findings resulted in a cooperation between B4Plastics and a start-up called Enzyan that helps companies to implement biocatalytic cascades in their production plants. Enzyan did an upscale of the first step of the PhD project which is the production of (S)- -hydroxy octanoic acid. The latter was intended for the synthesis of new polymer building blocks at B4Plastics. Cooperation between experts from the polymer and biocatalysis fields can lead to industrial innovation as it paves the way for a more sustainable industrial future. Furthermore, there is the possibility to transfer the knowledge on other P450 peroxygenases and also other substrates as dicarboxylic acids.

Impact on society

European society is increasingly aware of plastic pollution and there is a growing demand for sustainable alternatives. However, communication between society, government, industry, and academia often falls short. For instance, specific groups as consumers of plastic bags may not understand that biodegradability does not necessarily equate to compostability.

Throughout our project, effective communication between academic and industrial partners was crucial, revealing diverse strategies and perspectives. Projects like these can enhance understanding among various stakeholders. A notable success of our project was our press release which garnered significant interest from the public and is thereby strengthening consumer and policy makers awareness.

Visual Summary – Poster