Abstract

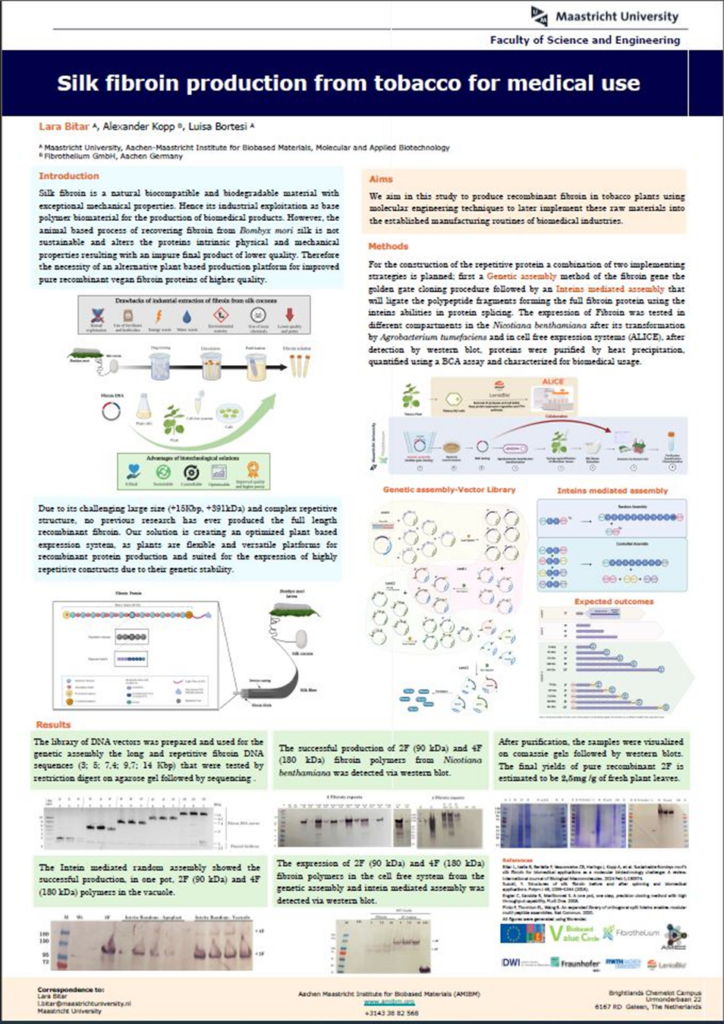

Fibroin, the main component of silkworms silk, is a natural biocompatible and biodegradable material with exceptional mechanical properties what makes it a valuable material in the biomedical industry. However, the process of recovering fibroin from Bombyx mori silk has quality, purity, sustainability and ethical drawbacks. Therefore, the necessity to develop a more sustainable production platform for recombinant vegan fibroin of improved quality. The fact that fibroin is a large and repetitive protein –at both the nucleic acid and amino acid levels- poses serious challenges to its recombinant production. We propose an optimized plant-based expression system for the recombinant production of fibroin. By combining two strategies: a DNA mediated assembly, [generating a versatile library of vectors creating a series of modular golden gate cloning steps to gradually assemble the fibroin gene] and an intein mediated protein assembly for the assembly of larger fibroin polymers, [exploiting an inteins mediated assembly to ligate polypeptide fragments into larger fibroin proteins] we successfully produced, purified and quantified vegan recombinant fibroin polymers (60 kDa, 115 kDa) from the tobacco plant N. Benthamiana. These recombinant proteins are now anticipated for industrial and medical testing.

Publications for Communication and Dissemination

| Action plans | Target actors/audience | Means | Timing | Links | ||

| Scientific Journal | Academic/Industry in biotech and wide range of professionals | Publication | Pending | – | ||

| Scientific Journal | Academic/Industry in biotech and wide range of professionals | Publication | Pending | – | ||

| Talk at Wageningen Univ. | Academic students/ professors | Presenting | September 2024 | – | ||

| Personal LinkedIn | Academic/Industry and public; wide range of professionals | Promotion | 2021-2024 | www.linkedin.com/in/lara-bitar | ||

| Fibrothelium LinkedIn | Academic/Industry and public; wide range of professionals | Promotion | 2021-2024 | https://www.linkedin.com/company/fibrothelium-gmbh/posts/?feedView=all | ||

| LinkedIn Biobased Value Circle | Academic/Industry and public; wide range of professionals | Promotion | 2021-2024 | https://www.linkedin.com/company/biobased-value-circle-network/ | ||

| ECB Conference- Rotterdam | Academic/Industry in biotech and wide range of professionals | Presenting | July 2024 | https://www.ecb2024.com/ | ||

| AMIBM summer event | Academic/Industry and wide range of professionals | Presenting | June 2024 | – | ||

| Training events Biobased Value Circle #7 in Netherlands | Academic/Industry and wide range of professionals | Presentation + Poster | May 2024 | https://biobased-valuecircle.eu/7th-training-event-symposium/ | ||

| ISPMF conference-Cape town | Academic/Industry in biotech and wide range of professionals | Presenting | May 2024 | https://www.ispmf.org/events | ||

| Patent | UM+ Fibrothelium | Scientific invention | Submitted in May 2024 | – | ||

| NWO life | Academic/Industry specialists in biotechnology and molecular biology | Poster + pitch Presentation | Planned –May 2023 | https://nwolife.nl/ | ||

| Netherlands Biotechnology Congress | Academic/Industry specialists in biotechnology and molecular biology | Poster + pitch Presentation | September 2023 | https://nbc.kncv.nl/ | ||

| Training events Biobased Value Circle #6 in Galway | Other ESRs and supervisors within the consortium | Presenting | November 2023 | https://biobased-valuecircle.eu/6th-training-event/ | ||

| Training events Biobased Value Circle #5 in Graz | Other ESRs and supervisors within the consortium | Presenting | May 2023 | https://biobased-valuecircle.eu/5th-training-event/ | ||

| Training events Biobased Value Circle #4 in Cologne | Other ESRs and supervisors within the consortium | Presenting | November 2022 | https://biobased-valuecircle.eu/4th-training-event/ | ||

| Scientific colloquium | Academic/Industry and general public at AMIBM | Presentation | September 2021 and December 2022 and December 2023 | – | ||

| Netherlands Biotechnology Congress | Academic/Industry specialists in biotechnology and molecular biology | Poster + pitch | October 2022 | https://nbc.kncv.nl/ | ||

| International Society for Plant Molecular Farming conference https://www.ispmf.org/rome-2022 | Academic/Industry specialists in Plants biotechnology | Poster + pitch | September 2022 | https://www.ispmf.org/rome-2022 | ||

| Training events Biobased Value Circle #3 in Netherlands | Other ESRs and supervisors within the consortium | Pitch | May 2022 | https://biobased-valuecircle.eu/3rd-training-event/ | ||

| Teaching PBL tutorial group | Students | course | October 2021 | – | ||

| Scientific Review: “Sustainable Bombyx mori’s silk fibroin for biomedical applications as a molecular biotechnology challenge: A review” | Academic/Industry specialists in biotechnology, biomedical sciences, material sciences and sustainability | Review paper- collaboration with other ESRs | April 2024 | https://www.sciencedirect.com/science/article/pii/S0141813024011772?via%3Dihub | ||

| Training events Biobased Value Circle #2 – online | Other ESRs and supervisors within the consortium | Pitch | December 2021 | https://biobased-valuecircle.eu/training/2nd-training-event/ | ||

| Training events Biobased Value Circle #1 – online | Other ESRs and supervisors within the consortium | Pitch | May 2021 | https://biobased-valuecircle.eu/training/biobased-value-circle-1st-training-event/ | ||

Protection of the acquired intellectual property (patents applications) etc.

A Patent was filed by UM and Fibrothelium for protection of the invention. The results are protectable until further decisions of licensing.

Impact on science and/or technology

The established library of vectors for the DNA modular assembly using the golden gate method is an important result that has versatile applications. By changing the inserted DNA sequence, this library allows the assembly of any type of repetitive or modular protein. It was tested by assembling various proteins using this library. This library can be used as an established platform or as reference for future work in the biotechnology field.

According to literature, producing the native size fibroin was never done before due to the complexity of the protein structure and length. By combining our two ligation strategies, we aim to produce of the full-size fibroin. When accomplished, it will have a high impact in the biotechnological field and especially in the plant biotechnology field because it will open opportunities for the production of large complex proteins in plants.

Impact on innovation (companies)

This research has a big impact on the biomedical/cosmetic industries especially the companies using silk fibroin as a base material for their production. Our work can be considered a starting point for an improved and sustainable Fibroin industrial production. Overall, the recombinant production of fibroin in plants has many advantages over its current extraction. Contrary to the industrial extraction, that exposes the proteins to high temperatures and toxic chemicals that causes their degradation, our strategy will allow to obtain intact pure recombinant proteins of consistent quality, major criteria for industrial production especially in the biomedical field. Another advantage of the recombinant production is the versatility of redesigning chimeric proteins with new functionalities or optimizing the protein structures by genetic manipulation in order to have better and more valuable properties.

From the sustainability point of view, instead of killing silkworms to obtain fibroin we use plants. This is very attractive not only for the biomedical but also for the cosmetic industry that now considers silk fibroin as a non-vegan product, limiting its usage in this growing market. Furthermore, the current industrial extraction involves many toxic compounds, by using biotechnological methods to produce recombinant fibroin in plants that do not require the usage of toxic chemicals would contribute in avoiding waste problems.

Having a stable BY2 cell line that secrets fibroin polymers is very important for developing future industrial platforms. Optimization and upscaling of the plant-cell cell bioreactors will allow to obtain larger amounts of pure intact proteins and bring this process towards an industrial scale.

Impact on society

Impact on patients, physicians and biomedical product industry: Fibroin is a very important material used nowadays for biomedical applications. When producing recombinant intact pure fibroin from plants we preserve the proteins’ structure and therefore mechanical properties. Eventually, we can provide better and safer biomedical products of higher quality that will be beneficial to the patients, protecting them from immune responses caused by the sericin residues remaining in the natural silk fibroin biomedical products. That will have also a positive impact on physicians that will feel reassured when using a safe product.

Cosmetics consumers and Animal welfare activists: The usual method of fibroin extraction from silk cocoons involves killing large number of silkworms. From one side that troubles the animal welfare activists since the process is considered unethical and involves animal sacrifices and from the other side such animal derived product is not used in the cosmetic industry that nowadays focuses on vegan cosmetics. By providing plant-produced vegan fibroin that can be used to manufacture vegan products for the biomedical and cosmetic industries we can have a good impact on these specific groups.

Impact on environmental activists/ policy makers/society in general: The current process of extracting silk fibroin from silk cocoons is considered not sustainable because it involves the usages of toxic chemicals and generates water, energy, organic and chemical waste. By using plants as production platforms, we provide a more sustainable alternative that gives people who care about the environment a greener choice.

These Impacts are not limited to a specific country as the products can be sold and shipped worldwide. The benefits to the biomedical industry will be limited to Fibrothelium due to a patent application unless the invention was licensed to a third party.

Visual Summary – Poster