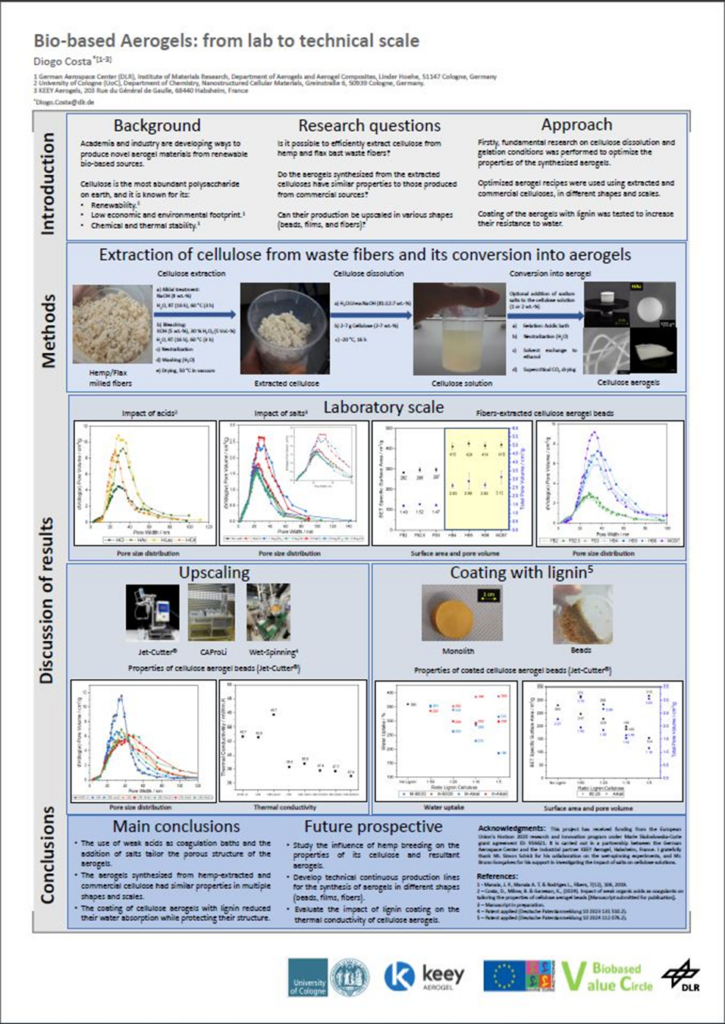

Abstract

This work focused on the synthesis of cellulose aerogels from hemp and flax waste bast fibers for thermal insulation purposes. These aerogels were produced in different shapes and sizes. The best synthesis recipes were chosen for upscaling and were applied using the Jet-Cutter® (beads), the CAProLi (Cellulose Aerogel Production Line, for sheets/films), and wet-spinning technologies (fibers). The aerogel samples were characterized by their chemical composition, morphology, structure, and others. Pure cellulose was extracted from the bast waste fibers and the addition of sodium chloride, and sodium sulfate to the cellulose solution accelerated its gelation while improving the internal structure of the aerogel samples. A smoother cellulose gelation was achieved when weaker organic acids were used as regeneration baths. The aerogels synthesized presented high porosities (over 80%), high specific surface areas (over 200 m2 g-1), and low densities (< 0.21 g cm-3). The upscaling of the synthesis of aerogels was effective for all equipment used with little differences between different scales and sources of cellulose (hemp and commercial). The thermal conductivity of the aerogels ranged from 37 mW m-1 K-1 to 40 mW m-1 K-1, providing space for further improvement. Soda lignin was effective as a coating agent for cellulose wet gels achieving a 40% reduction in water absorption for the coated aerogels. This approach has environmental and economic advantages compared to laboratory batch-wise synthetic routes, which contribute to the development of the industrial aerogel market and a circular bio-based economy.

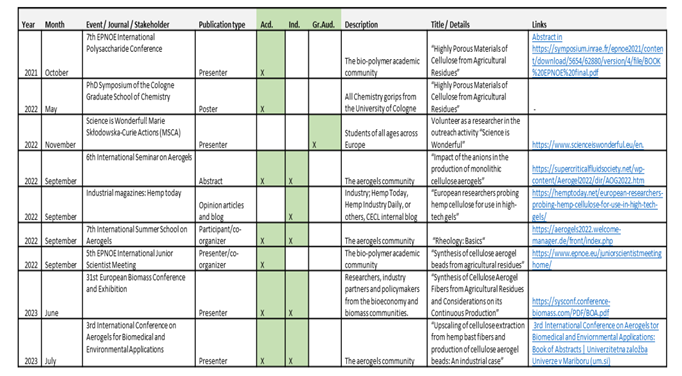

Publications for Communication and Dissemination

Protection of the acquired intellectual property (patents applications) etc.

Two patent applications have been submitted to protect intellectual property developed during this PhD. One patent application has been submitted regarding the development of a process for the “Continuous Neutralization and Solvent-exchange of Wet-gel Cellulose Fibers” (Deutsche Patentanmeldung 10 2024 115 066.1), whose invention was developed in collaboration with Simon Schick, ESR 7, as a common project of Strand 1. This invention concerns a method where cellulose wet gel fibers are continuously created, neutralized, and their solvent exchanged. The fibers collected are ready for drying and conversion into aerogels, saving time and resources compared with current batch-wise technologies.

A second patent application was submitted regarding the “Coating of Cellulose Wet Gels with Lignin” (Deutsche Patentanmeldung 10 2024 112 076.2). This invention concerns a simple method to coat cellulose wet gels with lignin, before their drying and conversion into aerogels. The coated aerogels maintain their internal porous structures while their surface is mostly covered with hydrophobic lignin, inducing water and moisture resistance properties to the aerogels.

Impact on science and/or technology

In this work, various experiments and studies were performed. The first topic focused on the extraction and characterization of cellulose from hemp and flax waste bast fibers. The extraction process was performed at laboratory scale and then scaled up for technical use, producing chemically pure cellulose without compromising the efficiency of the process. Before converting the extracted cellulose to aerogels, systematic studies were carried out on the dissolution and regeneration conditions of cellulose, followed by analysis of the synthesized samples.

Cellulose dissolution was achieved at -10°C in 30 minutes for 100 mL solution when a cooling plate was used, which allowed for faster dissolution compared to the standard method used in this work.

For regeneration, a general trend was observed. The slower the regeneration of cellulose, the more time was available to create a filigree 3D cellulose network where the formation of smaller mesopores was maximized to the detriment of macropores. The use of organic acids such as acetic, lactic, and citric acid as coagulants resulted in aerogels with higher specific surface areas and shifted their pore size distribution to smaller pores than the aerogels produced in HCl aqueous baths due to a promotion of smoother gelation. For salts, due to the increased complexity of the system, such linear conclusions were not as strict. The addition of NaCl and Na2SO4 favored faster gelation due to their affinity to water and increased the specific surface area of the aerogels due to the pores created when these salts were removed during the neutralization and solvent exchange phases. The addition of trisodium citrate increased the gelation point of the solution and sharpened the pore size distribution but, because of the bigger dimensions of the citrate anion and its organic character, did not increase the specific surface area of the aerogels as the other salts. The complex interaction between charged anions and cations with organic polymers in aqueous solutions still needs further understanding. Both sets of experiments provided tools to tailor the aerogels´ properties depending on the desired final application.

From these recipes, it was tested the synthesis of aerogels from extracted cellulose in different shapes and scales. The synthesized cellulose aerogel beads, sheets/films, and fibers from extracted cellulose, especially from hemp-extracted cellulose, had comparable properties to aerogels produced from commercial cellulose with the same recipes. The upscaling of their production using different equipment such as the Jet-Cutter and the CAProLi was successful while preserving their properties. These materials had high surface areas and low densities but were not considered superinsulators due to their high thermal conductivity (37 mW m-1 K-1 to 42 mW m-1 K-1). Other applications where they could be used include filters and biomedical applications due to their high surface area and biocompatibility. The lignin coating of the aerogels induced resistance to water absorption but not hydrophobicity.

This work contributes to a better understanding of the relationship between the synthetic conditions of cellulose aerogels and their properties. Based on this knowledge, the development of recipes for upscaling devices provides new opportunities for the industrial application and production of cellulose aerogels. The creation of cellulose aerogels from agricultural wastes with comparable properties to current alternatives promotes the valorization of biomass waste resources and the development of a circular bio-based economy, with economic, environmental, and social benefits for Humanity.

Impact on innovation (companies)

Despite efforts to upscale the synthesis of cellulose aerogels in various shapes, such as beads, fibers, and films, neither a scale production over 2 L nor a continuous production line was achieved. One proposed primary process for industrial scale production involved dissolving cellulose, regenerating it into a wet gel, and continuously processing it through neutralization, solvent exchange, and CO2 supercritical drying.

Previous works have focused on the sustainability and costs associated with synthesizing aerogels, comparing silica with bio-based alternatives at laboratory and technical scales. For all classes of aerogels and even with a recycling rate of 95%, ethanol remains the biggest contributor to the global warming potential (GWP) of their synthesis (50%). It is the main driver for abiotic depletion (fossil), photochemical oxidation, and release of respiratory organic compounds. This is because ethanol is produced from the hydration of ethylene, which is an energy-intensive process, and whose ethylene is mostly obtained from fossil sources. To mitigate these impacts, shorter solvent-exchange cycles with lower volumes are recommended, as well as recycling and using ethanol produced from fermentation of bio-based wastes. The use of supercritical CO2 in the drying process, even with 95% recycling rates, comprises 28% of the GWP for all classes of aerogels. The use of water has a significant impact, as distilled water should be used for the solvent exchange (the presence of salts contributes to the corrosion of the drying reactor), and needs to be purified from solvents and reactants. This consumes more energy and waste disposal-associated costs.

Regarding differences between silica and bio-based aerogels, no consistent data has been collected. While Wang et al. concluded that bio-based aerogels had from 75% to 92% lower GWP, energy consumption, and soil acidification potentials than silica-based aerogels, Antypa et al. found no difference between the silica and cellulose aerogels. Disposal emissions can be ignored for bio-based aerogels as they are degradable. Further impact is reduced if the aerogels are produced from agricultural wastes that would be disposed of otherwise, as in the case of the aerogels synthesized in this work from hemp and flax waste bast fibers. Concerning the upscaling of the aerogel synthesis and processing, previus studies registed a substantial improvement in the environmental impact of the process. The transition from laboratory to pilot scale resulted in an overall reduction of 40% in impact, namely a reduction of 70% for human health, consumption of resources, and GWP. Impact reductions achieved 90% when the scale passed to the industrial scale. This was due to the heat and solvent recovery that occurs at an industrial scale and to the lower production of waste per kg of product. Besides, at an industrial scale, the reactors have better insulation and a lower surface-to-volume ratio, resulting in minimal heat loss compared to laboratory scale. The infrastructure is not relevant as it comprises 1% of the impact, as well as transportation.

Based on this data, it can be assumed that upscaling the synthesis of cellulose aerogels to the industrial scale, especially those produced from renewable bio-based wastes, would bring economic and environmental advantages compared to the current laboratory and technical scale developed methods. The higher efficiency of the synthetic process, associated with the reduction of costs and larger production, would decrease the price of the aerogels and facilitate their large-scale introduction into the market. The upscaling of the synthesis of aerogels, in multiple shapes, studied in this work eases the development of a continuous industrial process for the synthesis of these materials.

Impact on society

The development of bio-based aerogels with multiple applications, from thermal insulation to filtration and biomedical technologies, from agriculture residues has a broad impact on different sectors of society. The more immediate impact is the creation of an efficient new sustainable thermal insulator that can be used by individual consumers and by professional classes such as architects and real estate developers. Its efficiency compared with current oil-based alternatives contributes to higher thermal comfort in homes and apartments, to higher energy savings, and the renovation of the urban landscapes, with gains in well-being for their citizens.

The valorization of biomass wastes would be particularly beneficial for farmers and their rural communities. These, especially in Europe, are characterized by older, poorer populations where the lack of economic opportunities leads to population decline and consequent reduction in available public services and quality of life. Creating new high-value products from wastes that, otherwise, would not bring any economic return, would increase the income of small-scale farms and promote the creation of new bio-based businesses. These require skilled and non-skilled labor, creating high-paying jobs in the rural world and fixing young people in these areas.

Besides the creation of more resilient rural communities, whose specificities and biomass resources vary from region to region worldwide, and the satisfaction of private and corporate clients who have a new bio-based sustainable product available, this work has geopolitical impacts as well. As these materials are produced from agricultural waste and not from oil-based sources and, if used as thermal insulators, contribute to lower energy costs, their use decreases the resource dependency on other countries. In a World increasingly multipolar, with geopolitical tensions and disruption of the logistic connections around the globe, it is essential to decrease energetic and resource dependency on foreign powers, especially if not allies. The valorization of local residues contributes to increasing the economic and energy resilience of each nation and, by promoting the development of rural communities, further favors national cohesion and solidarity.

Visual Summary – Poster