Abstract

In the area of disposable filter textiles such as coffee pads and hot seal teabags, the disposal of the product in household waste is the primary end-of-life (EoL) option. Due to the share of thermoplastic material in the filter textile (currently realized with PP, PET, PA, and PLA), sealing can be implemented for closure. At the same time, this share represents the most significant environmental impact when composting, as the product cannot be completely degraded. As the only bio-based and industrially processed plastic for this application, polylactic acid (PLA) cannot be broken down under home composting conditions. PLA can be composted in industrial facilities that use elevated temperatures of 58°C for degradation. It cannot be composted at home, where the temperature is lower at around 28°C.

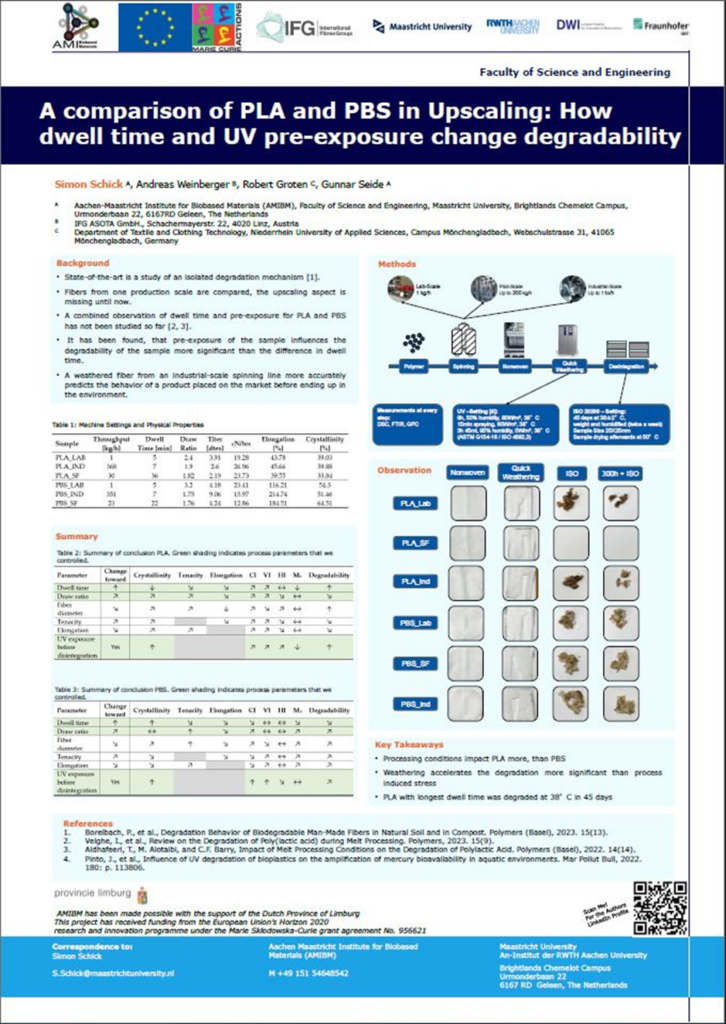

Therefore, it is necessary to evaluate other materials, a task undertaken as part of this project. Various home-compostable and industrially available biopolymers are initially spun alongside a state-of-the-art petrochemical polymer (PP) using the same machine and settings. In this comparison, PBS emerges as the top performer among the home-compostable polymers. The subsequent phase of the study focused on examining the impact of different dwell times during the spinning process as part of the upscaling process. This study focuses on spinning PLA and PBS on Lab, Pilot, and Industrial Scales. It was observed that PBS exhibits excellent process stability but is more susceptible to degradation when compared to PLA, which demonstrates the opposite behavior. By increasing the dwell time, the stress on the molecular structure of the polymer increases, and the degradation time of the fiber decreases. Nonetheless, if the samples are pre-exposed to UV radiation and hydrolysis in a quick weathering scenario, this pre-loading impacts the degradability more significantly than the dwell time.

Publications for Communication and Dissemination

| Action plans | Target actors/audience | Means | Timing | Status |

| Training events Biobased Value Circle #3 in Netherlands | Other ESRs and supervisors within the consortium | Presenting | May, 2022 | Done |

| Training events Biobased Value Circle #4 in Cologne | Other ESRs and supervisors within the consortium | Presenting | November, 2022 | Done |

| Training events Biobased Value Circle #5 in Graz | Other ESRs and supervisors within the consortium | Presenting | May, 2023 | Pending |

| Publication of #1 paper in Open Access | Wide range of professionals, general public | Publishing Paper | March, 2023 | Done |

| Publication of short article about my research | General Public, professionals | Publishing Article | October, 2022 | Done |

| Publication of #2 paper in Open Access | Wide range of professionals, general public | Publishing Paper | May, 2024 | Done |

| Publication of #3 paper in Open Access | Wide range of professionals, general public | Publishing Paper | June, 2024 | Internal Review |

| Publication of #4 paper in Open Access | Wide range of professionals, general public | Publishing Paper | July, 2024 | Finishing up |

Paper #2 is in Review process, Paper #3 is in the finishing stages, and Paper #4 is 50% done and planned to be handed in in late July 2024.

Links to the Publications:

- International Fibers Journal Article Issue 5, 2022, page 52: Fiber Journal (publicationprinters.com)

- Mdpi Polymer Published peer review publication: Polymers | Free Full-Text | Performance Spectrum of Home-Compostable Biopolymer Fibers Compared to a Petrochemical Alternative (mdpi.com)

- Mdpi Polymer Accepted peer review Publication: “A comparison of laboratory and industrial processes reveals the effect of dwell time and UV pre-exposure on the behavior of two polymers in a disintegration trial” Publishing shortly

Protection of the acquired intellectual property (patents applications) etc.

Mr. Diogo Costa and Mr. Simon Schick have written the first draft of a patent. The topic focuses on the production of aerogel cellulose fibers, with Mr. Costa providing the aerogel know-how and Mr. Schick providing the processing know-how.

Impact on science and/or technology

Until now, the degradability of home compostable biopolymers seems to be tailorable with the melt spinning process. If further trials confirm this, it can influence the innovation field in several ways.

Starting with material science and engineering, where material development could be advanced significantly. This advancement could spark formulations and production techniques where precise degradation profiles for specific applications arise. This would mean collaborations between chemists, material scientists, engineers, textile developers, etc., to explore new ways to control and tailor polymeric properties during processing.

It is continuing with product development, where the specific lifespan can be targeted. This enhances the functionality and user experience, starting with medical devices (that degrade in the body after serving their purpose) and continuing with agricultural films that decompose post-harvest. This would also tie into accelerated prototyping, where rapid testing and iteration of new product designs meet specific degradation criteria.

The Environmental and Sustainable sector would open the possibility for companies that could minimize waste and pollution. It would also contribute to new tools and methods for lifecycle assessments to push optimal product design connected to environmental friendliness.

Medical and pharmaceutical applications could revolutionize drug delivery by tailored degradation in the body. Tissue engineering, implants, and scaffolds that degrade as new tissue could also be used.

Tailored biopolymers can reduce the waste generated in packaging and Agriculture by degrading safely over a specific time. Developing biopolymers that degrade into beneficial soil amendments contributes to sustainable agriculture and better soil health.

The need to verify and standardize biopolymer degradability will drive the creation of new standards and certification processes, fostering innovation in compliance and testing technologies.

By designing the degradation of biopolymers, new markets can open up with entirely new applications. This will spark investments into research and development related to spinning, biopolymer synthesis, etc.

Overall, tailoring the degradation of biopolymers with the melt spinning process will have a significant impact on material science, product design, sustainability, medical, packaging, agriculture, and many more. It will not just enhance the already existing materials and applications but will also start an entirely new category of environmentally friendly and high-performing materials.

The research conducted in this project opens an avenue of interesting questions in different directions. First, the degradability tailoring should be confirmed on a machine, where different dwell times can be simulated as an isolated parameter. With this knowledge, the behavior of different polymers should be compared. Besides PLA and PBS, many other biopolymers are becoming more available on the market, starting with PHA. Also, the opening of new materials (Materials from the Glaukos Project (EU funding No. 887711), for example) could be of interest for those trials. By combining the knowledge gained in this and other projects, the speed of newly gained knowledge could enhance the applicability of biopolymers in everyday products.

Impact on innovation (companies)

The tailoring of biopolymers for their degradability will influence companies across various industries.

The customization part will open new ways for companies to enhance product development by defining specific degradation profiles for products for single-use and longer-term applications. This tailoring will allow companies to offer products to different market segments and consumer preferences.

With the environmental benefits, sustainability goals can be met, such as reduced environmental impact while minimizing waste and pollution.

By optimizing a product’s lifecycle, resource management can be tailored to different applications, where exchange intervals of products could be optimized. The costs related to end-of-life treatment can be managed, especially. By designing for an efficient degradation at the end of the use phase, cost-effectiveness and waste stream simplification narrow the overall costs involved.

By investing in technology to tailor degradability, companies will gain a competitive edge, which in turn will result in new patents and improved products.

Focusing on tailoring degradability will also change the supply chain, establishing new suppliers who can provide the necessary materials and technology to achieve tailored degradability.

On top of that, a positive brand image and consumer loyalty will result.

In summary, companies adopting the degradability of biopolymers with the spinning process will gain an advantage ranging from enhanced product offerings to a clear market differentiation. However, careful consideration of manufacturing processes, cost implications, and consumer education is also required.

Specifically tailored to the project-partner IFG ASOTA GmbH Linz, the performance spectrum of different biopolymers is always investigated on the machine park at hand, for all available polymers. The knowledge gained in this project ties into this databank seamlessly. The goal to tailor the degradation based on dwell time and surface area opens the door to introduce a application specific degradation profile for different fiber types. Along with other parameters, this could enhance the standing of the company on the market.

Impact on society

The impact on society will be significant and multifaceted, affecting different aspects.

This would start with significantly reducing plastic pollution, as products would start to safely degrade after their intended use phase. This could be connected to more efficient resource use by ensuring that materials decompose appropriately after fulfilling their intended purpose. By reducing the overall waste in nature, exposure to microplastic in everyday life would be reduced, leading to an improvement in public health.

The need for new technologies and processes to produce tailored biopolymers would create jobs in research and development, manufacturing, and environmental management, resulting in growth. Over time, using biodegradable biopolymers reduces costs associated with waste management and environmental cleanup, leading to benefits for industry and consumers.

With the implementation of biopolymer products without a change in experience, the user can help reduce waste production without sacrificing convenience.

With the increased availability and visibility of biodegradable products, attitudes toward environmental issues and sustainable materials are expected to change. More content surrounding biobased and biodegradable materials might interest schools and universities, fostering a new generation of scientists, engineers, and customers.

With possible international collaborations, which already take place, standards, policies, and behaviors related to biopolymers could be changed. Waste management in developing countries could be greatly improved, especially when a possible end-of-life is the degradability of products.

Overall, the tailoring of biopolymers’ degradability through the melt-spinning process could improve society significantly, including environmental sustainability, improved public health, economic benefits, and cultural shifts towards more sustainable practices.

Brought to one specific topic, this topic ties into the solution of stopping the microplastic problem. When the production process alters the degradability of biopolymers, this would stop the accumulation of nondegradable plastics in the environment and, therefore, the overall microplastics challenge.

Visual Summary – Poster