Abstract

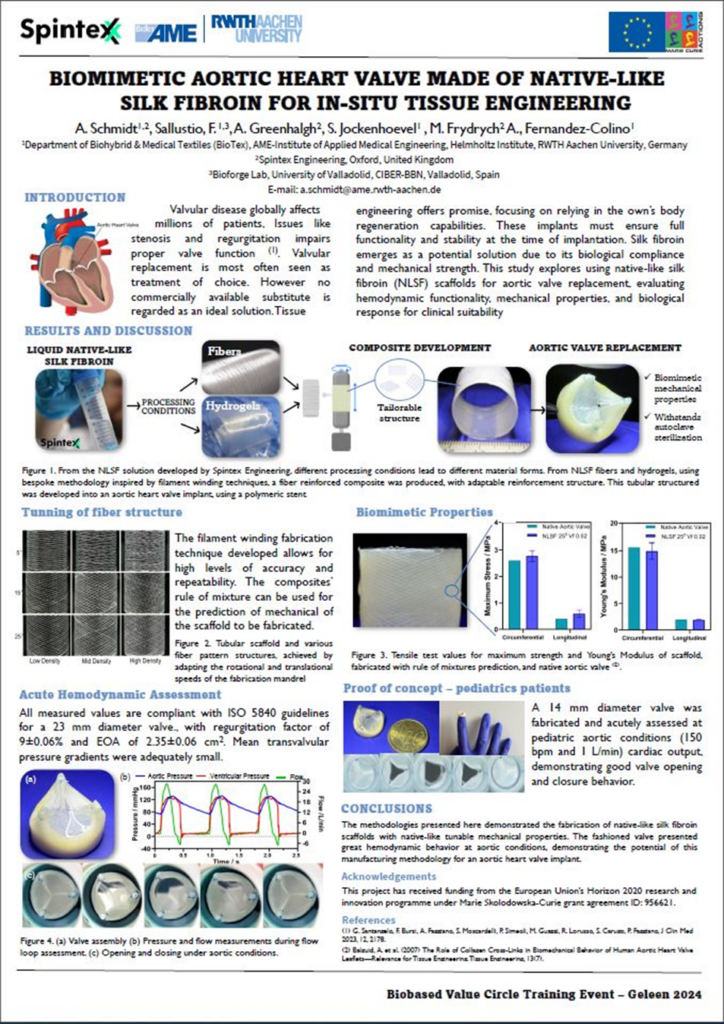

Current heart valve replacements meet only partially the clinical demands for patients in need of such a device. Low functionality span, calcification, hemocompatibility issues, and in particular, the need of life-long surgeries for pediatric patients are commonly encountered issues. Therefore, there is a pressing need for advanced replacement solutions. In this study, we tackle this necessity by designing aortic heart valves endowed with customized fiber reinforcements and hydrogel matrix, both purely fabricated from native-like silk fibroin. To predict the mechanical behavior of these innovative scaffolds, a mathematical model is employed, utilizing the properties of the scaffolds’ constituent materials, and experimentally validated through tensile testing. Valve hemodynamics of biomimetic rational-designed configurations were thoroughly assessed mechanically, and hemodynamically in accordance to ISO 5840 guidelines. Valves demonstrated compliant acute hemodynamic performance under aortic, as well as favorable biocompatibility based on cytocompatibility studies. The developed silk fibroin-based aortic heart valve shows promise as a novel replacement solution to address the limitations of current surgical standards.

Publications for Communication and Dissemination

Publications

Submitted publication: “Manufacturing of anisotropic protein-based scaffolds to precisely mimic native-tissue mechanics”, Advanced Material Technologies Journal.

In preparation: “Native-like Fibroin Scaffolds as Biomimetic Aortic Heart Valves for In-Situ Tissue Engineering”

| Action plans | Target actors/audience | Means | Timing |

| Training events Biobased Value Circle #3 in Netherlands | Other ESRs and supervisors within the consortium | Presenting | May, 2022 |

| European Society of Biomaterials Conference – Bordeaux | Academic/Industry within biomaterials research field | Poster presentation | Semptember, 2022 |

| Training events Biobased Value Circle #4 in Cologne | Other ESRs and supervisors within the consortium | Presenting | November, 2022 |

| Training events Biobased Value Circle #5 in Graz | Other ESRs and supervisors within the consortium | Presenting | May, 2023 |

| LinkedIn Biobased Value Circle | Academic/Industry and general public; wide range of professionals | Promotion | March, 2023 |

| European Society of Biomaterials Conference – Davos | Academic/Industry within biomaterials research field | Poster presentation | September, 2023 |

| Training events Biobased Value Circle #6 in Galway | Other ESRs and supervisors within the consortium | Presenting | November, 2023 |

| Final Symposium in Geleen | Other ESRs and supervisors within the consortium. Academic/Industry and general public; wide range of professionals | Poster | May, 2024 |

Protection of the acquired intellectual property (patents applications) etc.

Currently, the material in development by Spintex is protected by trade secrets.

Impact on science and/or technology

The impact of the project’s development on science surrounds the ability to manufacture a single material composite tubular structure, with adaptable mechanical properties. Such tubular structures allow for ease of production and high repeatability. From the tuning of the fibre structure, we were able to closely to mimic those of native tissues, for a load-optimised aortic heart valve prototype.

The scaffold structure developed is fully degradable, and yet biomimetic and mechanically robust. In addition, displays the possibility of autoclave sterilisation, making it a suitable candidate for an off-the-shelf in-situ tissue engineering application, where no cell pre-seeding is required. The bioactive implant shall rely solely on the body’s foreign body reaction and regeneration abilities for a successful integration of the implant.

Impact on innovation (companies)

The material developed by Spintex Engineering is currently being tailored for textile applications in the fashion industry. Through the development of this project, it further expands the possibilities for the potential of material inclusion in alternative markets. The results of this project will serve as an initial step for the understanding of its potential in the Biomedical industry, and as a vector for positioning Spintex’s potential in the current medical market. Not only envisaging cardiovascular implants, but also as a possibility to other medical applications.

Impact on society

In contrast with the high incidence of valvular pathologies in the world’s population, only two prosthetic valve replacement technologies are available in the market to this date. The existing replacements have helped save countless lives; however, they are still associated to either poor hemocompatibility issues, or low durability due to calcification and structural degradation of the valve leaflets. In addition, the available implants lack on the ability of growth and remodelling with the patient. Therefore, in the case of a paediatric patient, multiple surgeries would be required for adapting the implant size throughout the patient’s growth.

The implant in development in this project intends to address such issues associated with the current heart valve implants. The material in development comprises of a bioactive scaffold, that after implantation, through the patient’s own regeneration capabilities, would develop into a living implant integrated by the patient’s own living tissues. This would allow for regrowth and remodelling, like in a living tissue, benefiting in particular paediatric patients, reducing the incidence risk of revision surgeries

Visual Summary – Poster